Our team of professionals is ready to apply years of experience to any directional drilling applications. This includes the development of well plans using industry-leading technology, HawkEye 3D, which allows for three-dimensional viewing of well plans, torque and drag analysis, hydraulic programs, and anti-collision planning.

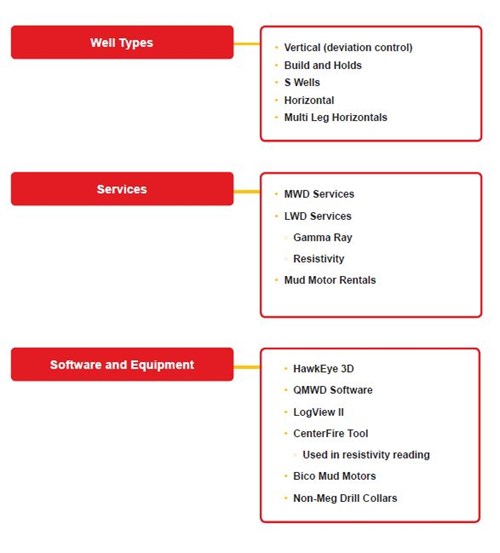

Having the tools to do the job is an important measure of a directional drilling company. Our team of directional drillers bring years of experience in drilling many different well types, including but not exclusive to; build and hold, horizontal, or multi-leg horizontals wells. Equipped with BICO Evenwall motors gives Viking Services a competitive edge, allowing an increase in motor durability and overall motor performance compared to conventional motors. We understand that creating strong productive wells is the goal of the drilling industry and that the use of our Logging While Drilling (LWD) packages can offer the information necessary to make the real-time decisions that can make long-term impacts.

Localized in Diyarbakir, the Down-Hole Maintenance Shop, and the M/LWD Technical and Operations Center provide the direction and servicing for our field operations. Having a full level III servicing facility in the country allows us to minimize costs and decrease turnaround times. Viking Services realizes each client will have unique needs and understands that the directional drilling business is an actively changing environment and is constantly updating our drilling practices by assessing new technologies. We look forward to creating solutions to any directional drilling challenges the industry can provide.